We noticed that JavaScript is currently disabled on your browser. For the best viewing experience, please enable JavaScript.

Compass Industrial Group can help with your denesting applications. We have several options for denesting and tray handling. Check out our denesting videos to see them in action.

The revolutionary TrayFlow Denester can denest a wide range of trays and cups without vacuum cup or gripper contact. TrayFlow denesters are extremely high speed denesting machines with reliable single lane capabilities up to 120 trays per minute. These machines are very robust and versatile, with a minimum amount of moving components. The TrayFlow uses a direct drive servo motor and a planetary gearbox for precise control and excellent reflex action. Easily handles fragile, lightweight trays at high speed without damage, and equally capable with almost any tray type. Due to the design, the TrayFlow is able to survive in the most arduous of environments with the most minimal of maintenance requirements.

Multiple Packaging Products on a Single Machine!

To get the best return on your investment this capability is a must, therefore it is also essential that the machinery performs to its maximum potential for every selected product. We have the right equipment for simple precise and repeatable set-up.

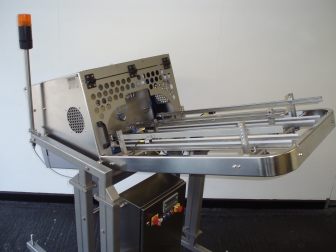

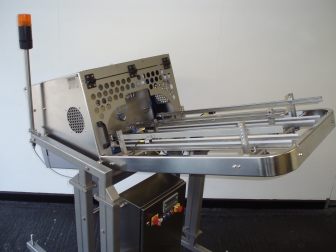

The ServoFlow Pick & Place Denester is for tray denesting, direct lid placement or picking and placing of other products. As the name suggests, the heart of the unit is a robust servo motor and planetray gearbox. Due to its robust design, the ServoFlow is able to perform secondary operations such as denesting and placing lids directly onto containers, following through with a pressing action to completely close the container in a single action. The modular design enables us to offer these machines in a multitude of standard based formats, including single and double arm models with single or multi-lane magazines to suit any application.

Our denesters can be selected with the following add-on options:

After you trays are denested why not build in a buffer system and meter the trays into your production equipment. Compass Industrial Group can help with various solutions.